The evolution of baggage handling at airports and cruise ports

Whether flying or maritime, passenger numbers continue to rise as air travel becomes more accessible and cruises expand their routes.

TAWI produces ergonomic lifting solutions to improve the efficiency of airport operations, including baggage handling, cargo loading, and supply handling.

You have successfully submitted your enquiry. Someone from our company will respond ASAP

TAWI’s ergonomic lifting solutions for airports are a significant development in airport operations. With over a decade of experience and more than 650 installations in over 80 airports worldwide, TAWI (formerly Vaculex) is improving baggage handling, cargo management, and ground operations through smart, user-friendly vacuum lifting technology.

Learn how smart lifting tools are reshaping baggage flows in our free white paper “The evolution of baggage handling at airports and cruise ports”, which is available at the top of the profile.

Many airports choose TAWI’s baggage handling systems due to their superior ergonomic benefits. Using the company’s systems, airports can reduce physical strain by 80% and lessen the load on baggage handlers’ bodies, which helps to minimises fatigue and musculoskeletal injuries. TAWI’s vacuum lifting systems are also proven to help prevent injuries and reduce many of the high risks associated with repetitive manual baggage handling, including back, shoulder, and arm injuries. With less risk and physical strain, airport personnel experience greater job satisfaction, enhanced wellbeing, and improved productivity.

Preventing strain-related injuries among staff also helps to reduce sick leave costs, meaning that airports experience absenteeism-related disruptions and reduced worker compensation claims, helping them to save money in the long term. Improving working conditions will help to increase job satisfaction among baggage handling staff, leading to lower staff turnover and better retention. This results in reduced hiring and training costs.

Using TAWI’s lifting systems helps staff to work more efficiently and improve productivity as they will be able to process the same volume of luggage but with significantly less physical effort. The company’s systems can also accommodate a range of baggage types, including oversized or irregular items, and each system integrates with an airport’s existing infrastructure. This leads to improved efficiency, optimised workflow designs, and smooth operational transitions. With over 650 successful installations, TAWI’s team of experts are able to quickly install and adapt any systems, ensuring a smooth transition and minimal operational disruption.

TAWI’s range of lifting solutions can assist with baggage handling, air cargo processing, and airline and airport catering. Baggage handlers can lift up to six tonnes of luggage per shift, but TAWI’s vacuum lifting technology reduces the physical effort required, making the baggage handling process easier and quicker. The company’s systems can be used in many airport processes, including sorting and loading baggage onto carts at baggage makeup areas, handling and transferring baggage for connecting flights, assisting with baggage claim area loading, and transporting baggage to checked baggage reconciliation areas (CBRA).

London Stansted Airport, the UK’s third largest, handles over 27 million passengers annually. Manual baggage handling used to be leading cause of injuries and inefficiency. To address this, Stansted partnered with TAWI to install ergonomic lifting systems, making health and safety a top priority.

TAWI assessed Stansted’s operations and challenges to recommend the most suitable baggage lifting solutions. This resulted in the installation of equipment that meets the airport’s specific requirements, including:

These lifters are now used throughout Stansted’s baggage handling operations, allowing staff to safely and efficiently lift and move luggage of all sizes and shapes. The systems have minimised manual lifting, reduced the risk of injury, and improved overall workflow. As a result, baggage handlers experience less physical strain, and the airport benefits from increased efficiency and a strong return on investment.

“Manual handling is one of our top three lost time injuries we have with staff every year. Because we have refreshed all our baggage system, that allows us to mitigate the risk of manual handling, lost time events at the lowest level,” said Head of Baggage and Security Engineering Steve Radford.

Air cargo operations involve repetitive lifting, sorting, and transferring freight items. TAWI’s solutions prevent overexertion and speed up processes while ensuring precision handling and minimal manual handling risks. The company’s systems can help to sort incoming freight, manage oversized or awkwardly shaped packages, and load/unload cargo containers.

TAWI’s systems can also be used to ergonomically handle supplies for airport staff working with meal trays, food containers, and beverage supplies. Airports can use the systems to load meal trays into catering trolleys or lift boxes, crates, or sacks containing food and beverage supplies.

In airports, there are often many tight spaces and areas with low ceilings, such as baggage handling areas. This makes it difficult to install lifting equipment. TAWI solves this by offering compact and space-efficient lifting solutions that work in low-clearance environments while still providing the support need.

Airports work under tight schedules. From baggage handling to cargo processing, workers need to lift and transfer items quickly to keep operations running on schedule. TAWI’s high-speed lifting systems are designed to maximise efficiency without compromising safety, allowing airport staff to move luggage, freight, and equipment faster and with minimal physical effort. TAWI’s airport lifting solutions enable seamless, rapid lifting across various airport tasks, which helps to reduce delays and ensure smooth operations, especially in high-traffic areas where speed is critical.

Not all baggage is a standard suitcase and luggage can be heavy and oddly shaped, requiring special handling. TAWI’s customisable lifting solutions can be adapted to various sizes and shapes, reducing the risk of damage and making handling easier.

When working with TAWI to install airport lifting solutions, TAWI specialists first begin with a pre-installation consultation and on-site analysis. This allows TAWI’s experts to design specially tailored solutions that seamlessly integrate with an airport’s existing infrastructure and operational requirements.

Following this, TAWI will then install the required lifting solution and train airport staff. Using experience from hundreds of installations, TAWI will install and setup the system seamlessly, with minimal interruptions to workflows. Staff will then be given hands-on training and get to practice with the new system.

To continuously support clients after the installation is complete, TAWI establishes a long-term partnership through continuous support, training, routine maintenance, and services. The company will also relocate any lifting equipment as required and customise solutions as operational needs evolve.

Customers can upgrade their airport and airline operations using TAWI’s ergonomic lifting solutions to improve baggage handling, cargo processing, and airline and airline catering operations.

Whether flying or maritime, passenger numbers continue to rise as air travel becomes more accessible and cruises expand their routes.

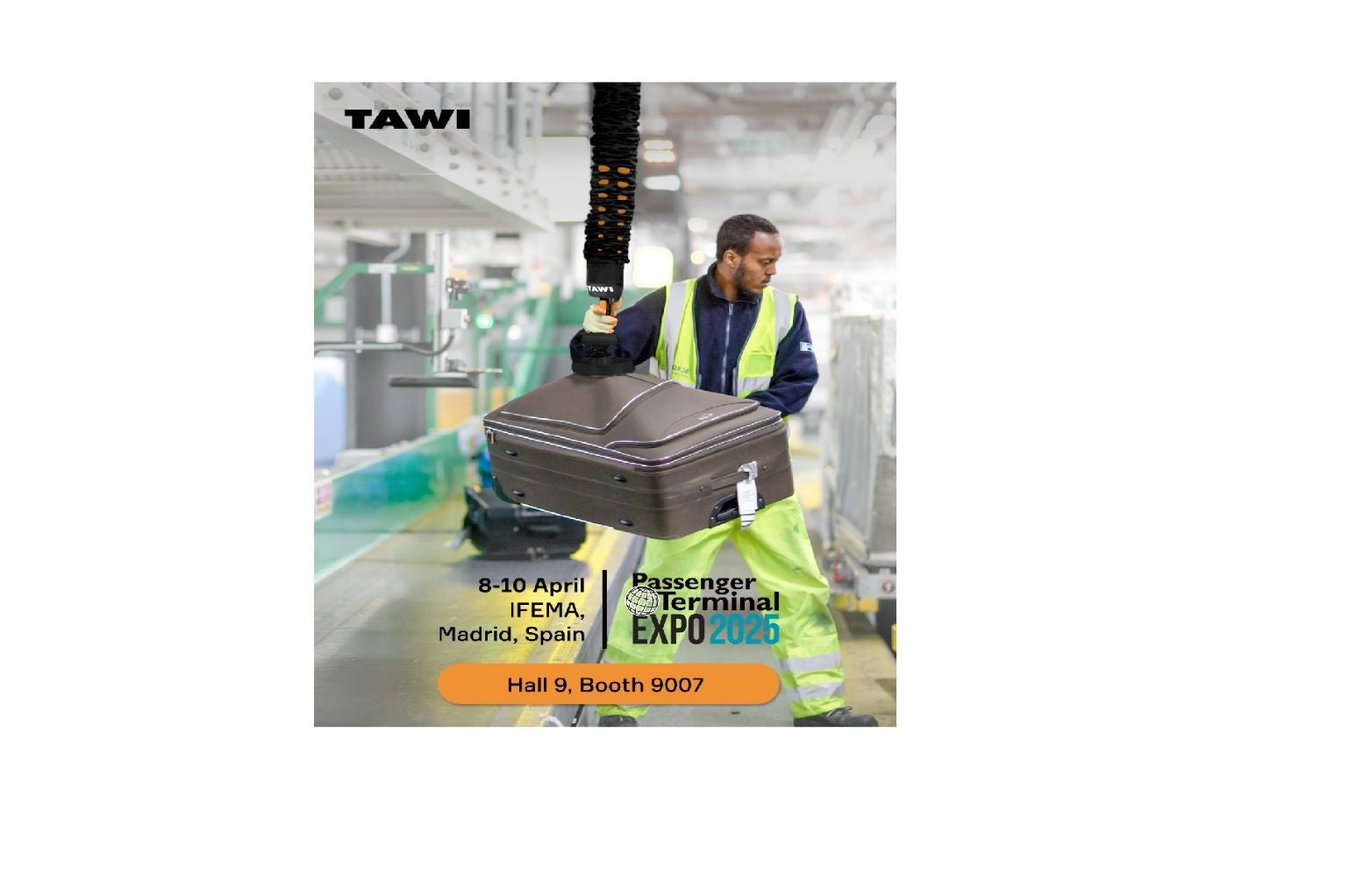

Passenger Terminal Expo is the leading international event for airport operations, aviation technology, baggage handling systems, and terminal design.

More passenger traffic and a higher demand for better service require more efficient baggage handling systems.

When you are ready to solve the cost of baggage handling and protect your bottom line, reach out to TAWI.

TAWI's lifting equipment addresses the unique challenges faced by airports, cargo handling and airlines.

We recommend scheduling annual maintenance to keep your equipment in top condition and ensure maximum safety and productivity.

The ergonomic one-hand grip and quick-release function ensure smooth workflows.

The Container Unloader enhances logistics workflows, reduces manual strain, and adapts perfectly to high-volume, fast-turn environments.

This versatile solution is ideal for order picking and manual material handling.

With a lifting capacity of up to 270 kg (595 lbs), it handles catering supplies, logistics items, and other materials with ease.

TAWI’s Low Built Cranes offer an efficient, space-saving solution.

Lift boxes, sacks, bags, drums, sheets and much more.

Our dedicated service team works closely with you throughout the entire lifecycle of your equipment to ensure reliable performance.