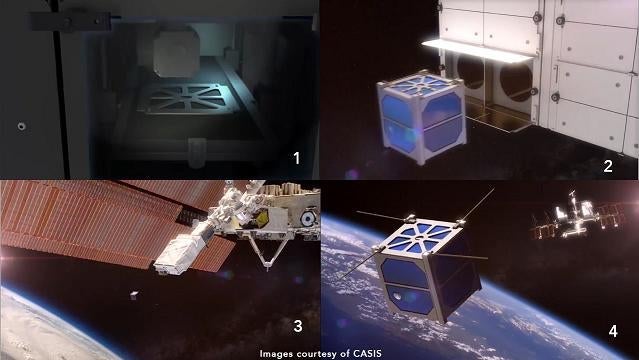

Made In Space has partnered with commercial low-Earth orbit services provider NanoRacks to offer on-orbit assembly and deployment of small satellites.

Named Stash & Deploy, the new satellite deployment service will leverage NanoRacks’ expertise in CubeSat deployment and Made In Space’s in-space additive manufacturing capabilities.

Discover B2B Marketing That Performs

Combine business intelligence and editorial excellence to reach engaged professionals across 36 leading media platforms.

The service will make use of a satellite deployment platform, such as the International Space Station, to store various standard and customer-specific satellite components for rapid manufacture of CubeSats.

Made In Space president Andrew Rush said: "This is a fundamental shift for satellite production.

"In the near future, we envision that satellites will be manufactured quickly and to the customer’s exact needs, without being overbuilt to survive launch or have to wait for the next launch."

After an optimised structure is created and the necessary components are integrated on orbit, the satellite will be deployed into low-Earth orbit.

US Tariffs are shifting - will you react or anticipate?

Don’t let policy changes catch you off guard. Stay proactive with real-time data and expert analysis.

By GlobalDataThe process will require a fraction of the time necessary to build, launch and deploy satellites from the ground.

Made In Space CTO and co-Founder Jason Dunn said: "Made In Space was founded with the belief that one day entire spacecraft will be manufactured in space.

"With Stash & Deloy, NanoRacks and Made In Space make the first step towards this goal."

The company’s additive manufacturing facility will create a custom structure for both the space environment and customers.

NanoRacks CEO Jeffrey Manber said: "Looking out a few years this option may be more desirable than launch and deploy."

Image: Stash & Deploy satellite manufacturing and assembly on-orbit service. Photo: courtesy of Made In Space, Inc.