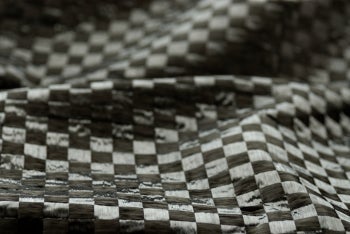

Sweden-based Oxeon has developed a new carbon fabric known as TeXtreme, which could substantially reduce the weight of existing aircraft and help airlines achieve significant savings in fuel costs.

Replacing the existing traditional materials with TeXtreme carbon fibre, in composite panels for instance, could lower the weight of airliner to such an extent that potential fuel cost savings could be in excess of €43,000,000 per annum, according to Oxeon.

Discover B2B Marketing That Performs

Combine business intelligence and editorial excellence to reach engaged professionals across 36 leading media platforms.

In addition, the reduction of CO2 emissions resulting from weight savings of this scale would be about one million laps across the world counted in flight miles.

Unlike the conventional method, which uses yarns for the production of textile reinforcement, TeXtreme is produced by using spread tows.

TeXtreme leads to weight savings no other type of composite reinforcement can match, the company said.

Carbon fibre and other composite reinforcements are already being used in the aerospace industry and a wide range of other markets where there is a need to reduce component weight.

US Tariffs are shifting - will you react or anticipate?

Don’t let policy changes catch you off guard. Stay proactive with real-time data and expert analysis.

By GlobalDataOxeon marketing and sales vice-president Andreas Martsman said that an investment from airlines in TeXtreme would actually save money and reduce the environmental impact.

"If all the airlines and their manufacturers would do this, the potential fuel savings and effect on CO2 emission is enormous," Martsman said.

"To save millions in fuel costs and at the same time contribute to a greener and more sustainable world should be in everyone’s interest," Martsman said.

Oxeon stated that if the airlines could take advantage of the potential in weight savings through use of TeXtreme, they could generate significant savings, which could lead to better profits and allow enhanced service levels, availability and prices for travelers globally.

TeXtreme Spread Tow carbon reinforcements are currently being used in aerospace applications, Formula One, advanced and various sport products such as bicycles.

Oxeon, based in based in Borås, develops, produces and markets patented Spread Tow carbon reinforcements for achieving surface smoothness, significant weight savings, improved mechanical properties and new design possibilities.

Image: The use of TeXtreme carbon fibre fabrics in composite panels of an aircraft could significantly lower the weight of airliner, leading to fuel cost savings and lower CO2 emissions. Photo: courtesy of Oxeon AB.