Scottish sustainability driven leather company Muirhead has unveiled a new aviation seat foam, BioPRO, marking an advancement in the industry's sustainability efforts.

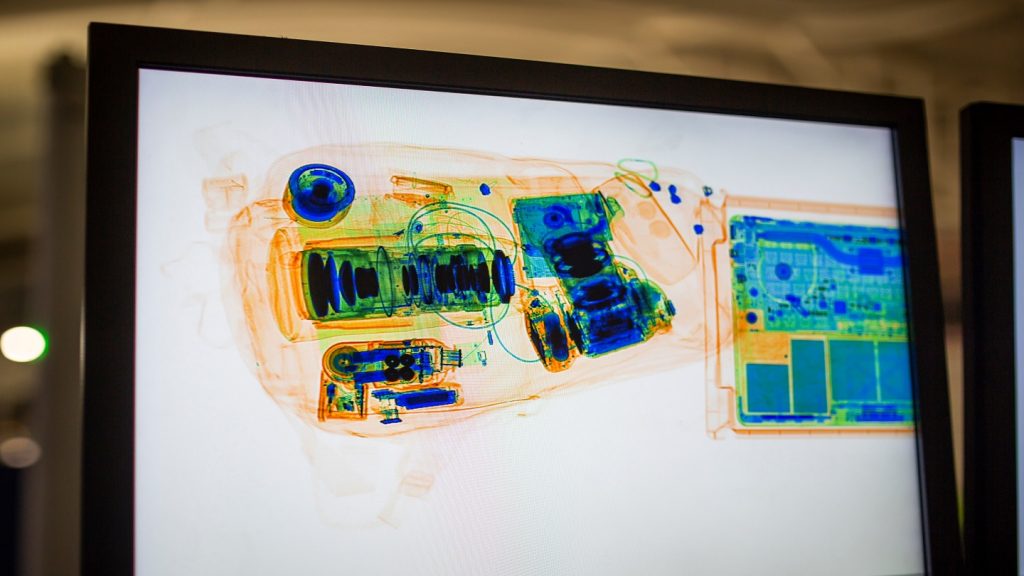

This product offers an eco-friendly alternative to traditional foams, featuring a 20% protein content that replaces harmful chemicals and enhances durability and fire resistance.

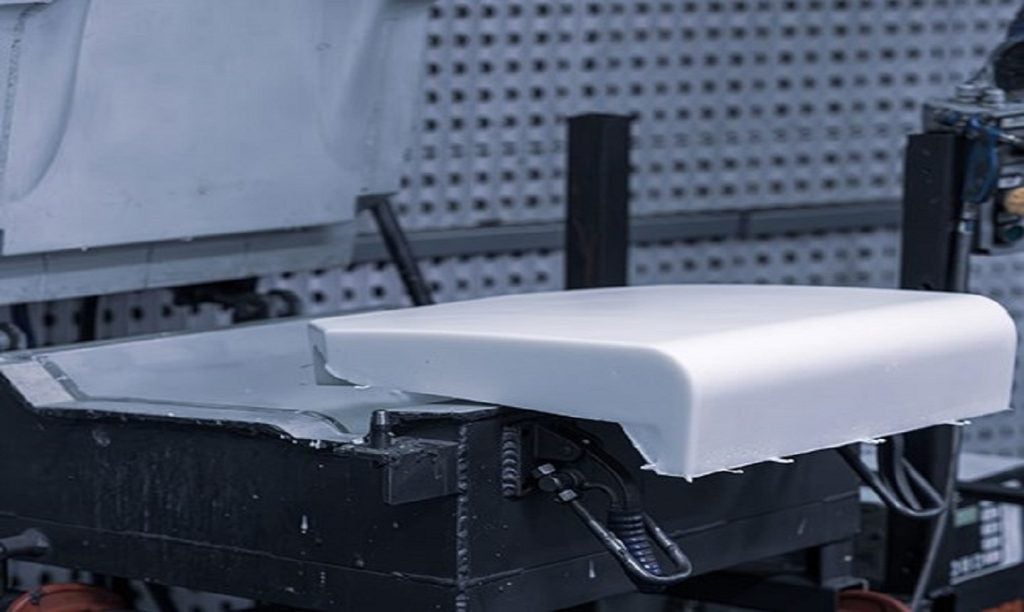

BioPRO foam is designed to meet the exact specifications of the aviation sector, including shape, weight, and density.

The foam serves as an eco-friendly, sustainable alternative for seat cushions that substitutes fossil fuel-based materials, leading to a notable decrease in carbon emissions within aircraft interiors.

It is developed through a moulding process that generates zero waste during production.

Unlike other bio-content foams, BioPRO's collagen-based technology offers enhanced comfort and longevity, according to the company.

Muirhead innovation and sustainability head Dr Warren Bowden said: “The key aspect is that the tertiary amine groups of the hydrolysed protein are bonded to the other ingredients, forming stable bonds and producing a more functional material.”

BioPRO's moulded design offers precision and zero waste, while its lightweight yet durable nature meets stringent aviation standards.

The foam's adaptability ensures tailored comfort for passengers, with formulations that can be adjusted for specific needs.

The company’s in-house design and testing capabilities provide a customised, high-performance seating solution that maintains consistency and aesthetics across the cabin.

Its comprehensive solution includes pre-fitted seat covers and cushions, optimising assembly time and operational efficiency, noted Muirhead.

Muirhead foam technology expert Scott Hadley said: “First we look at the end shape. We design moulds in-house and gather info to create our base chemistry.

“We blend the chemicals in various ways, then inject the mix into the mould under pressure and heat. It’s actually a simple process, all the work is in the front-end chemical recipe.”