For over 50 years, Blast Deflectors, Inc. (BDI) has provided airports, airlines and aircraft maintenance companies with cutting-edge solutions for jet-blast and ground run-up noise problems. Its deep understanding of the aerodynamic and acoustic theories of this field combined with its real-world experience from thousands of jet-blast deflector installations and more than 35 completed ground run-up enclosures makes BDI unique.

Jet-blast screens, jet-blast fences and jet-blast deflectors

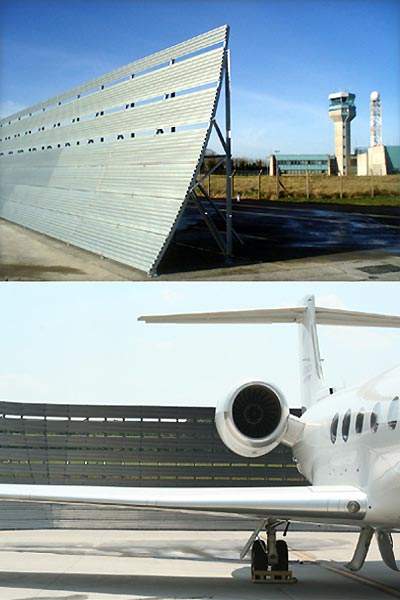

By focusing exclusively on jet-blast and run-up noise, BDI has earned a reputation for expertise, integrity, and long-term customer commitment. Its range of jet-blast screens, jet-blast fences and jet-blast deflectors (JBD) along with its ground run-up enclosure technology allows airports, designers, planners and consultants to improve the safety and environment of airports and the communities that surround them.

Jet-blast protection from taxiing aircraft

Since the days of the first jet airliners, BDI has worked to address the jet-blast danger of maneuvering aircraft, which can create significant hazards for people, vehicles, aircraft and buildings on and near airports. Jet-blast from taxiing aircraft can be effectively controlled using an adequately designed jet-blast deflector, screen or fence. BDI offers a range of solutions designed specifically to create a safer environment at airports.

BDI’s jet-blast deflectors meet the specifications of aviation authorities worldwide and have been installed in over 58 countries. BDI’s deflectors can be shipped anywhere in the world and are used by airports as a tool to create usable space in areas that would otherwise be unusable due to jet-blast hazards.

Jet-blast deflectors range

BDI studies the aircraft mix, available space, required protection, aesthetic requirements and portability requirements for each project to identify which of its range of over 45 models is most suitable. With heights ranging from 1.82m (6ft) to 11m (36ft), configurations include:

- Curved jet-blast deflectors

- Vertical jet-blast fences

- Jet-blast screens (angled and vertical)

- Special version for ILS protection

- Portable versions

Jet-blast deflectors for full-power velocities

Aircraft maintenance procedures often require running engines at high-power settings. These tests allow technicians to monitor power plant performance and to conduct engine manufacturers’ prescribed test sequences. This type of testing is called a ground run-up. Ground run-ups are performed at idle, partial power and takeoff / full power. Ground run-ups can last from a few minutes up to, in some instances, more than 45 minutes.

The jet-blast from an aircraft engine running at high power can create hazardous conditions for a considerable distance behind the aircraft. For example, a B777-300ER running at takeoff power produces a jet-blast envelope that exceeds FAA guidelines for safety for more than 609m (2,000ft) behind the engine.

The most practical treatment to address this issue is a blast deflector rated for full-power jet-blast velocities. BDI offers a range of blast deflectors designed specifically for aircraft run-ups. Standard models include deflectors rated for takeoff power for the following aircraft classifications:

- Wide-body jets (including the MD-11)

- Narrow-body jets

- Business jets

- Piston aircraft

- Afterburner military aircraft

Noise protection from full-power engine testing

It is critical that maintenance operations perform ground run-ups as needed without restrictions so that revenue-generating schedules can be maintained. Since ground run-ups are typically performed at night when aircraft are out of service and available for maintenance, run-up noise can be a challenging issue for airports. Depending on the aircraft and engine type, run-up noise can be heard for a considerable distance around airports.

Ground run-up enclosures

If run-up noise is an issue, a ground run-up enclosure (GRE) may be an ideal solution. A GRE is a facility designed to minimise the acoustic impact ground run-ups have on communities surrounding airports. Additionally, a GRE protects the immediate surroundings from hazardous high-velocity jet exhaust.

BDI pioneered the field of GRE facilities and have patented technologies that increase both the usability and noise reduction of their state-of-the-art run-up enclosures. BDI has built run-up enclosures to accommodate all types of aircraft, from small general aviation aircraft up to the A380 and the B777, in countries across the globe.

Recently completed GRE projects include:

- Bangkok (Thailand) 2011

- Bogotá (Colombia) 2011

- FedEx (Memphis) 2009

- Emirates Airlines (Dubai) 2008

- Sofia (Bulgaria) 2008

- Norfolk International Airport 2007

- Kuala Lumpur 2007

- Budapest (Hungary) 2013

- Detroit Metro Airport 2012

- Vancouver (Canada) 2012

- Zurich (Switzerland) 2012

- Spirit of St. Louis Airport 2011