Flexco

Conveyor Belt Splicing and Maintenance

Subscribed

You have successfully submitted your enquiry. Someone from our company will respond ASAP

About Us

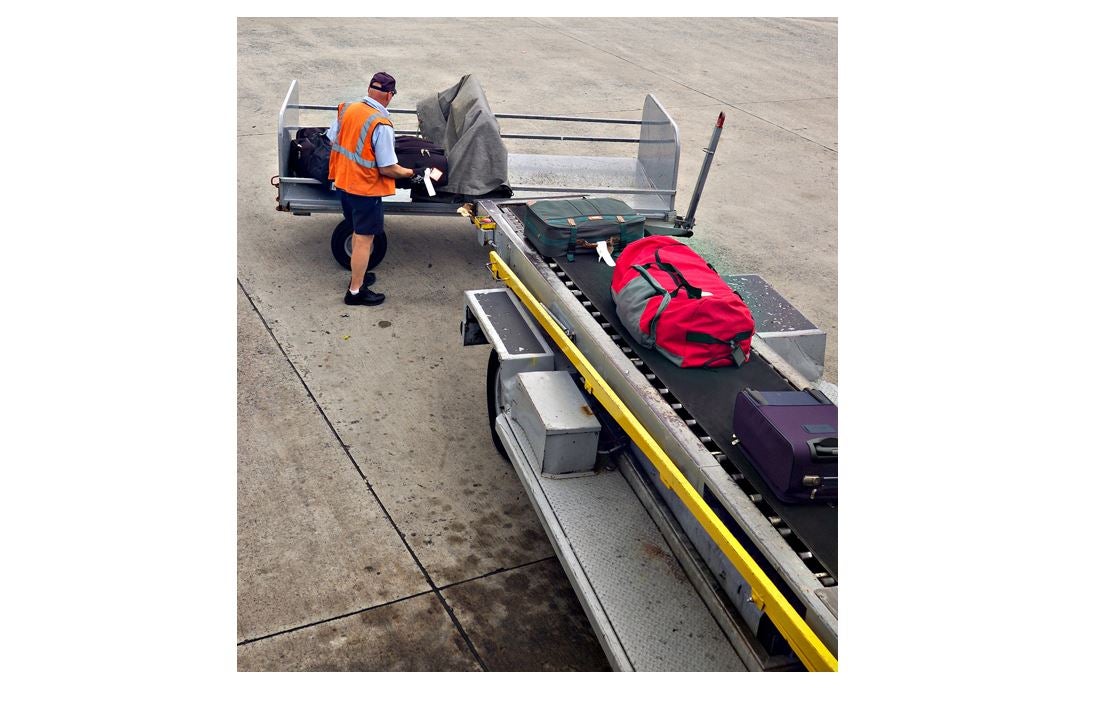

From baggage check-in to the depths of an airport’s baggage handling system, the most respected name in belt conveyor solutions is Flexco. The company’s products set the airport industry’s standard for conveyor design, installation, and reliability.

Airports around the world turn to Flexco for belt conveyor solutions that help maximise conveyor uptime and efficiency, promoting fewer missing bags, and increasing worker safety. Flexco offers the most comprehensive selection of quality belt conveyance enhancement and maintenance products in the industry, all while providing customers with unsurpassed product and application support.

Baggage jam reducing conveyor transfer plates

Baggage jams, often caused by luggage wheels, straps, or foreign objects becoming lodged into conveyor transfers, are a constant headache for baggage handling system (BHS) operators. Flexco’s Segmented Transfer Plate solutions are designed to create a tight seal at conveyor transfer points, eliminating the most common causes of baggage jams. Each segment’s tight fit to the belt creates a safer work area for employees; especially those that are working closely with belt conveyors.

Endless splicing for baggage scanning

The Flexco line of endless belt fabrication solutions have revolutionised endless belt splicing. Capable of splicing, separating, and punching, the Flexco Ply 130™ separator, Pun M™ mobile finger punch, and Novitool® Aero™ Press work together to make endless splicing faster, easier, and more cost effective. A complete endless splice now takes just ten minutes.

Endless splicing offers a smooth, fully-integrated belt splice, with minimal risk of snagging, tearing, and wearing down conveyor components or conveyed baggage. When scanning baggage, endless spliced belts will not interfere with metal detection or sensitive X-ray scanning equipment.

Conveyor belt fasteners- Alligator® spiral lace

Increasing demand for security scanning belts has increased the need for a non-metallic splice. The Alligator® spiral lace meets that demand, as it is a low profile, non-marking, hinged splice that is ideal for security belts.

Alligator spiral lace is vulcanised directly into the belt and is performed by belt fabrication shops. It is available in a variety of sizes and features either black or white materials. Typical applications for an Alligator spiral lace are security X-ray scanning belts.

Mechanical belt splices

A reliable mechanical belt splice can be installed in less than 20 minutes. All installation tools are lightweight and have been designed to be used directly on the conveyor. Overall, quicker installation means less downtime and fewer late bags, and mechanical fasteners give users the rapid ability to create a splice on the conveyor with just one installer.

As a mechanical splice is visible, any wear or deterioration is immediately apparent. Replacing or repairing a mechanical splice is easy and can be completed during scheduled periods of downtime. When conveyor maintenance requires belt removal, simply remove the hinge pin and the belt easily opens. Then, insert a new pin, set the tension, and the belt is back in business.

Conveyor belt fasteners- Clipper® wire hooks

For quick splice installation, rely on Clipper® wire hooks. Since its inception, the Clipper wire hook system has earned a reputation for continued innovation and proven performance.

Clipper wire hooks have been designed with a variety of different wire diameters, leg and point lengths, metal strip lengths, and styles, such as Unibar® and carded. All Clipper splices are machine applied for quicker downtime turnaround and greater consistency with splice installation. Typical applications include virtually all conveyors in baggage handling systems, such as baggage transport systems, check-in conveyors, and power curve/turn conveyors.

Conveyor belt fasteners- Alligator® staple fasteners

Alligator® staple fasteners offer a simple installation process and a strong, long-lasting splice. The Alligator staple splice gains its strength from the compression fit of the plate onto the belt and the ability of staples that cleanly penetrate through and cross-clinch into a pocket on the underside plate.

Alligator Ready Set™ staple fasteners are available in both steel and stainless steel, with the staples pre-staked into the fastener for quicker, easier installation. Typical applications for BHS are mobile aircraft loading conveyors.

Conveyor belt maintenance tools

In addition to mechanical fasteners, Flexco also provides a complete family of belt maintenance tools, such as the Roller Lacer® Gold Class™. This versatile and portable tool is designed for a quick and simplified hook installation. It significantly reduces operator fatigue and speeds up wire hook installation, without sacrificing precision.

The Roller Lacer Gold Class can be driven by a cordless drill (18V or higher) or operated manually using a handle or ratchet. The integrated belt support shelf aligns perfectly with the center of the hooks, allowing the installer to easily guide the belt into them, which saves precious time during critical breakdown situations.

The Flexco Smart Clamp™ belt clamping system is the safest, fastest, and strongest belt clamping system available for common belts found in baggage handling systems. In total, it is perfect for securing belt ends during maintenance, pulling the belt into position, and pulling the belt together, allowing for quicker hinge pin installation.

With the Flexco Laser Belt Square, belt squaring is made easy and can even be performed on worn belts. The vertical fan shape beam displays perfectly on the integrated targets (or any vertical surface) that are placed 10ft (3m) down the belt. Simply pivot using the spring-loaded belt edge location pin to find the common belt edge. Then, the 90° adjoining laser reveals a perfectly located cut reference line. Finally, mark the line with a writing utensil and the belt is ready to be cut.

For belt cutting that is consistently safe and fast, turn to the Flexco 845LD belt cutter. Its fully contained blade gives users the ability to make a perfectly safe cut in a single pass.

Contact Details

Email Address

Address

Downers Grove,

IL 60515,

Other,

United States of America