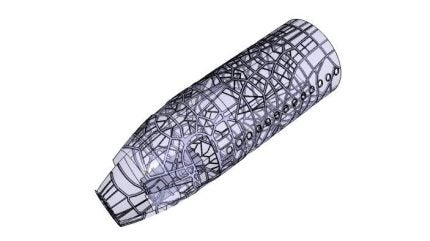

France-based company STELIA Aerospace has collaborated with Constellium, Centrale Nantes and CT Ingénierie to develop a demonstrator for metallic self-reinforced fuselage panels using additive manufacturing or 3D printing technology.

The demonstrator features stiffeners that were directly manufactured on the surface of the fuselage.

Discover B2B Marketing That Performs

Combine business intelligence and editorial excellence to reach engaged professionals across 36 leading media platforms.

The stiffeners are currently attached to the fuselage panels with fixing screws and occasionally welding, but the new process could eliminate the need of adding stiffeners separately to the fuselage in future.

The 1m² demonstrator was produced by a robotic tool, employing the process of depositing aluminium wire merged by an electric arc, known as wire arc additive manufacturing (WAAM).

Development of the new panel stiffener design is a result of a fuselage topological optimisation studies carried out by STELIA Aerospace and CT Ingénierie for several years.

It is also a part of the Developpement de la Fabrication Additive pour Composant Topologique (DEFACTO) project between STELIA Aerospace, Constellium, Centrale Nantes and CT Ingénierie.

US Tariffs are shifting - will you react or anticipate?

Don’t let policy changes catch you off guard. Stay proactive with real-time data and expert analysis.

By GlobalDataThe DEFACTO project is jointly funded by French Directorate General for Civil Aviation (DGAC) and the partners involved.

Launched in 2014 by STELIA Aerospace, the project seeks to conduct topological optimisation studies associated with 3D print demonstrators for elementary parts such as fittings, large dimension parts, including frames and large sub-assemblies.

STELIA Aerospace CEO Cédric Gautier said: “With this 3D additive manufacturing demonstrator, STELIA Aerospace aims to provide its customers with innovative designs on very large structural parts derived from new calculation methods (topological optimisation).

“Through its R&T department, and thanks to its partners, STELIA Aerospace is, therefore, preparing the future of aeronautics, with a view to develop technologies that are always more innovative and will directly impact our core business, aerostructures.”

STELIA Aerospace is currently studying 3D printing technology, in collaboration with Constellium and Ecole Centrale de Nantes.