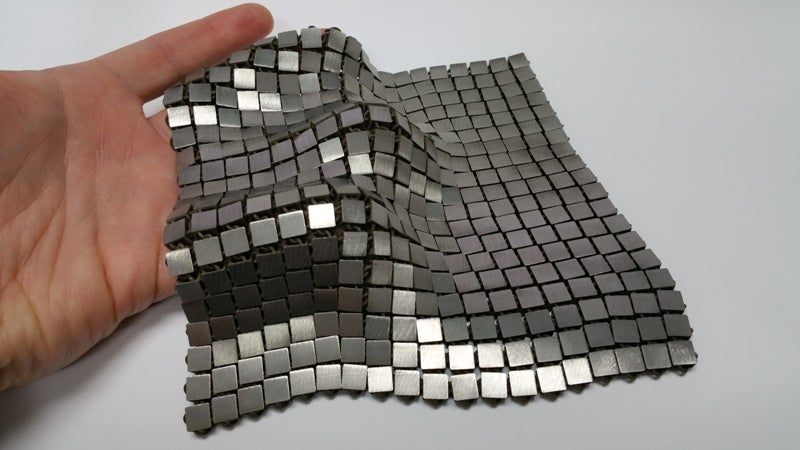

Scientists at Nasa’s Jet Propulsion Laboratory (JPL) in Pasadena, California, US, have developed 3D-printed metal fabric prototypes for various space applications.

Developed by JPL systems engineer Raul Polit Casillas and his colleagues, the foldable fabrics are used for large antennas and other deployable devices.

Discover B2B Marketing That Performs

Combine business intelligence and editorial excellence to reach engaged professionals across 36 leading media platforms.

It could also be used to protect a spacecraft from meteorites, capture objects on the surface of another planet, or for astronaut spacesuits.

The flexible material can also be folded over uneven terrain, creating ‘feet’ that won't melt the ice under them.

With an appearance similar to chain mail with small silver squares strung together, the newly created fabrics mainly perform four functions, namely reflectivity, passive heat management, foldability and tensile strength.

One side of the fabric reflects light, and the other absorbs it, acting as a means of thermal control.

US Tariffs are shifting - will you react or anticipate?

Don’t let policy changes catch you off guard. Stay proactive with real-time data and expert analysis.

By GlobalDataCasillas said: “We call it '4D printing' because we can print both the geometry and the function of these materials.

“If 20th century manufacturing was driven by mass production, then this is the mass production of functions.

“I can programme new functions into the material I'm printing. That also reduces the amount of time spent on integration and testing. You can print, test and destroy material as many times as you want.”

Developed with funds from JPL’s early-stage technologies research programme, the new space fabrics are expected to be used in future space missions.

The involved researchers are also planning to manufacture the fabrics in space in future.

Image: A metallic ‘space fabric’ created using 3D printed techniques that add different functionality to each side of the material. Photo: courtesy of Nasa/JPL-Caltech.