UK-based aerospace components maker GKN Aerospace has partnered with Durham University to develop and employ a test method that can precisely measure progress in aircraft wing drag performance.

The test is being used to find surface coatings that will cut down drag by 25%compared to standard aircraft surfaces and tested in typical aircraft cruise conditions.

Discover B2B Marketing That Performs

Combine business intelligence and editorial excellence to reach engaged professionals across 36 leading media platforms.

According to GKN, these coatings should have the ability to sustain a certain level of performance over a period of five years, which is the life span of the external paint system of an aircraft.

The project is under GKN’s future wing research programme, Validation and Integration of Manufacturing Enablers for Future Wing Structures (VIEWS) that seeks to develop new wing design, production and assembly technologies to near market readiness.

The Department for Business, Innovation and Skills, Aerospace Technology Institute (ATI) and Innovate UK granted funds and provides support to VIEWS.

In May, engineers at GKN’s Luton, UK-based site and a team from Durham University’s school of engineering and computing sciences commenced work on the project. After six months, they completed the first tests, where twenty coated surfaces were measured for their drag performance.

US Tariffs are shifting - will you react or anticipate?

Don’t let policy changes catch you off guard. Stay proactive with real-time data and expert analysis.

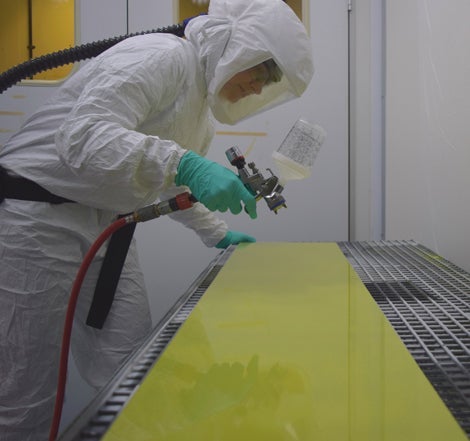

By GlobalDataCurrently at the development phase, tests are being conducted on various low drag surfaces, the coatings of which are being developed by GKN.

The development phase is expected to end by mid-2016.

GKN Aerospace engineering and technology senior vice-president Russ Dunn said: "Smooth and clean aerodynamic surfaces reduce the drag of the aircraft as it moves through the air.

"In some areas of the aircraft, for example the wing leading edge, the laminar flow (smooth continuous flow) of the air is typically spoiled by tiny changes in geometry and surface cleanliness.

"This causes the air flow to become turbulent, increasing drag, which in turn increases the engine power, and hence fuel, required to travel a given distance."

With its initiative to reduce aircraft drag performances, Durham University expects to help aircraft decrease fuel consumption and CO2 emissions.

Image: GKN Aerospace and Durham University to develop aircraft a wing drag performance measuring process. Photo: courtesy of GKN Aerospace.