Gerald R. Ford International Airport (GFIA), the second busiest airport in Michigan, is located approximately 13mi (21km) southeast of Grand Rapids, the biggest city in West Michigan, US. The airport is managed and operated by the Kent County Department of Aeronautics.

Earlier known as Kent County International Airport, it was re-named in 1999 in honour of Gerald. R. Ford, the 38th President of US, who served West Michigan as a US Congressman.

In 2014, the airport recorded an all-time passenger record by serving more than 2.33m passengers. It handled more than 75,000 aircraft operations and 82m pounds of cargo in the same year.

The airport offers non-stop service to 22 major destinations with 120 daily non-stop flights. It generates annual revenue of more than $3.1bn in West Michigan and employs more than 1,500 people.

The airport recently completed runway and concourse renovations, and launched construction of a fixed base operations terminal facility to improve facilities for passengers and operators.

GFAI terminal features and facilities

Gerald R. Ford international airport features a single terminal comprising of two levels. Level one opens to two concourses, A and B, which have seven gates each for arrivals and departures.

Passenger facilities on level one include the baggage claim area, airline counters, food court, rest rooms, game rooms, kid’s zone, police station, news and gift store, ATMs and shoe shine service.

Level two houses the Department of Aeronautics office, observation deck, Michigan room, Golden Eagle room, Transportation Security Administration, Gerald. R. Room, Grand Rapids room, Kent room, and rest rooms.

Concourse A has gates designated from A1 to A7 and features a security check point, food and beverage outlets, help centre, ATM, news and gift store, flight information desk and family assist rooms. Concourse B has gates from B1 to B7 and features similar facilities to Concourse A.

Concourse expansion and renovation

The two concourses were expanded and reopened in January 2015. The $12.3m expansion added new amenities and provided a new look to the concourses. Newly added facilities on Concourse B are two new airline gates, new signage, passenger hold rooms, terrazzo flooring, gate seating, the MI tap room restaurant and bar, and Grand Rapids magazine travel store.

Renovations on Concourse A included passenger hold room expansion, new seating, carpeting, upgrades to food and beverages stores, a new Grand Rapids magazine travel store, business area with expanded work space and charging stations.

Capital improvement projects at GFAI

The GFIA’s Capital Improvement Plan (CIP), which will include projects from 2015 through 2020 with a total investment of $95m, was approved by the airport Board in October 2014.

The plan includes construction of a consolidated checkpoint and marketplace, reconstruction of the terminal apron, a master plan update, and reconstruction of the north and east parking lots. It also includes resurfacing a portion of the airfield perimeter road, and mid-term maintenance items associated with the public parking structure.

Gerald. R Ford Airport runways

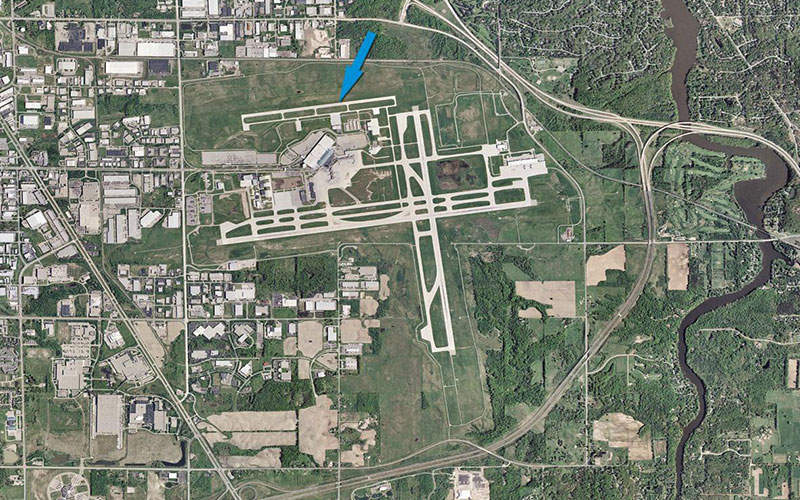

The GFAI features three runways designated 17/35, 8R/26L and 8L/26R. Runway 17/35 has a concrete-paved surface and is 8,501ft-long and 150ft-wide. Runway 8R/26L is 10,000ft-long and 150ft-wide and is covered with a concrete surface. Runway 8L/26R has an asphalt-paved surface and is 5,000ft-long and 100ft-wide.

The third runway, 8L/26R, was recently reconstructed by replacing its degraded surface. The runway, towards the north of the terminal building, was originally developed to accommodate smaller general aviation and flight training activities. The continued growth of the flight training programme at West Michigan Aviation academy deteriorated its condition over the years.

The reconstruction project, which began in June 2015, included more than 57,000yd³ of excavation and 14,000t of asphalt and was completed in October. The renovated runway has the ability to provide high-quality training to next-generation aviators.

Parking at GFIA

The Detroit Metro Airport in Wayne County, Michigan, is still undergoing a further round of reconstruction and redevelopment.

Parking at the airport is a four-level concrete structure with more than 4,000 parking spaces. It features a 600ft-long, 200ft-wide and 55ft-high curved glass canopy that joins the parking building with the terminal. The roof is covered with curtain wall, terra cotta panels and precast panels.

Level one offers covered, short-term parking facility and houses rental car facilities and access ways. While level two offers covered long-term parking facility, level three offers both covered and uncovered, long-term parking facilities and level four offers long-term parking. Other facilities at the parking garage include elevators, stairs, handicap parking, vehicle ramp and pedestrian walkway.

The fourth level of the garage, opened in November 2015, was open earlier, but now has a new deck roof. The open roof prevented parking at the level during the winter months due to the accumulation of snow. A $17.3m deck roof was, hence, planned to expand the facility. It opened 1,138 additional covered parking spaces bringing the total covered parking spaces at the airport to 4,172.

Ground handling facilities

Landmark Aviation operates ground handling facilities at the airport. The FAA- certified firm offers aircraft maintenance services, fuel services, both into-plane and retail fuel services, and aircraft de-icing services.

Landmark broke ground for a new fixed base operations (FBO) terminal facility at the airport in October 2015. The new facility will be located on a 16.8-acre site and includes construction of a 23,750ft² terminal and an 18,750ft² hangar constructed of pre-engineered steel. A 5,000ft² office space will be built adjacent to the hangar.

The FBO terminal will include a two-storey atrium to allow natural lighting and will be built using eco-friendly materials. Construction of the FBO is expected to be completed by summer 2016.

Construction partners for the project include Owen-Ames-Kimball as the construction manager, Prein & Newhof as the geotechnical engineer, and Butler Manufacturing serving as pre-engineering builders.

The architectural and design contract was awarded to Rivers & Christian, Tammy Edmonds Design and CHA.