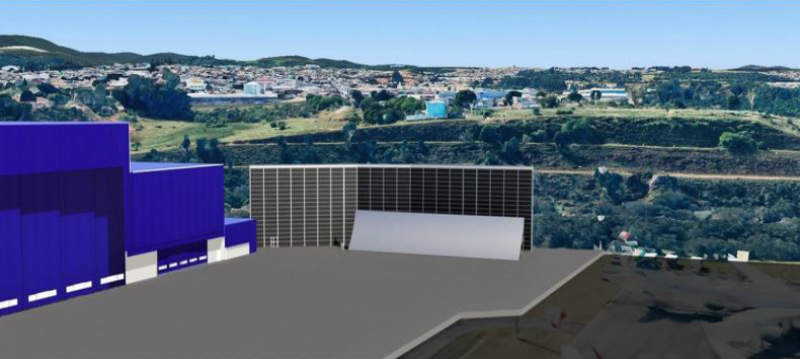

The new Ground Run-up Enclosure (GRE) to be installed at Guarulhos International Airport in São Paulo, Brazil, during June 2018 is under construction at VALIS Engineering.

The installation is due to take 45 days. The facility has been conceived to mitigate the noise impact of aircraft engine testing while preserving the exhaust fluid flow characteristics of aircraft engines, thereby reducing downtime for engine testing.

Guarulhos Ground Run-up Enclosure (GRE): An integrated solution incorporating Jet Blast Deflector & Acoustic Barrier.

Afer a jet engine has been overhauled or has undergone the replacement of parts, it is normal to run the engine up to full thrust to test it.

Urban airports surrounded by residential areas often specify that engine tests be conducted within a ground run-up enclosure so that the engine noise and high energy exhaust from jet engines can be reduced.

VALIS HEL model Jet Blast Deflector

A jet blast deflector (JBD) is a safety device that redirects the high energy exhaust from jet engines to prevent damage and injury. The structure must be strong enough to withstand high heat and speed air streams.

VALIS Jet Blast deflectors are made from high strength, hot dip galvanized steel to ensure maximum resistance and durability to high temperatures and engine exhaust speeds. VALIS Jet Blast deflectors contain the registered JETBLOCK® safety system that prevents deflector surfaces from detaching even in cases of accident.

COMPLAGE® Sound Barrier System

The function of the acoustic barrier is to absorb the noise generated by aircraft engines when operating on the ground. VALIS Engineering sound barriers combine two types of acoustic elements: a cladding acoustic panel and a diffraction controller device.

Tested according to European standards, VALIS AIRCOUSTIC® panels are classified as A4 and B3, with the highest levels of sound absorption and insulation. Manufactured with a distended aluminum front face and a steel structural casing, AIRCOUSTIC® panels have a perfect convergence between durability, structural stability and cost.

The interior of the panel consists of an inert and non-combustible high-density material. The surface finish of the panels is in thermo-lacquered polyester powder painting.

The absorbent face of the panels has a variable transparency that maximizes noise absorption while minimizing the ingress of water and debris. The major cause of inefficiency in acoustic barriers is the diffraction of sound waves at the top. VALIS noise barriers include a diffraction-controlling device: DCDT®.

The DCDT® is a product patented by VALIS Engineering that absorbs noise at the top of the acoustic barrier and through its shape reduces the diffraction of acoustic waves, thus improving the angle of the acoustic shadow zone as well as the aerodynamic performance of the ensemble.