Farnborough Airport (FAB) in the UK has commenced construction on a new hangar facility with an investment of £55m.

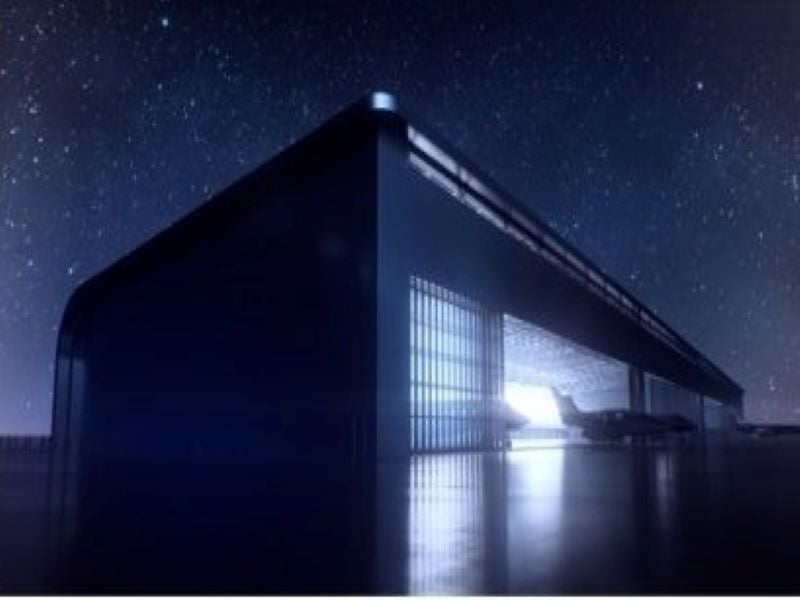

Dubbed Domus III, the 175,000ft² hangar will serve the next generation of business aeroplanes.

In addition, the sustainably designed hangar will help meet the increasing presence of electric vertical takeoff and landing (eVTOL) aircraft.

Domus III will offer hangarage that is anticipated to expand Farnborough Airport’s hangar space by more than 70%.

The construction work is planned to be completed in 75 weeks while the airport will continue to operate during this period.

This hangar facility will have various sustainable features, including translucent automated doors and improved natural light penetration.

The door design will enable large unhindered access to help enhance aircraft manoeuvrability.

Furthermore, it will incorporate intelligent lighting, eco-friendly heating systems and a fully integrated building control and energy monitoring system, as well as allow rainwater harvesting.

McLaughlin & Harvey and Gebler Tooth were selected as contractors for the management of the project.

McLaughlin & Harvey is the principal contractor that will set up their site and welfare cabins besides preparing designated areas for the delivery and installation of materials.

Various enabling works, including the installation of an on-site concrete batching plant, will be initially carried out to minimise the need for off-site deliveries and excess road journeys.

Commenting on the development, Farnborough Airport CEO Simon Geere said: “We want our customers to choose Farnborough Airport not only because of our market-leading facilities and award-winning levels of customer care but also because of our unrivalled sustainability credentials.”

Farnborough Airport serves more than 800 international direct connections.