Vantage Technology is the industry leader in explosionproof (flameproof) connectors for commercial and military aircraft hangars. Vantage manufactures GD series power and AF series control connectors that are UL and CSA certified to the US National Electrical Code Article 500 and ATEX certified to international flameproof standards.

Vantage connectors have a 45-year record of safe and reliable service in ground power receptacle units and below grade pits; as bulkhead-mounted receptacles; and on interconnect power cables. We work with customers on integrated system designs and hazardous area compliance and we are proud of our exceptional service and after-sales support.

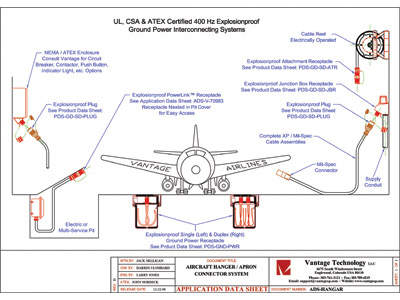

Hangar ground power receptacle

The Vantage ground power receptacle burst into prominence in the 1970s with its selection by the US Air Force for its C5A hangar program. Unlike pits, a ground power unit mounts flush to the concrete deck, housing one or two receptacles and any combination of push buttons and pilot lights for point-of-use control. Best of all, the ground power unit carries multiple third-party certifications from nationally recognized testing labs for use in aircraft hangars around the world.

Whether for military bases like the new F-35 hangars at Eglin AFB in Florida or large commercial hangars for the A-380 airplane at Air New Zealand in Auckland, Vantage ground power units meet and exceed the most stringent installation requirements.

Hangar service pits and receptacles

The Vantage PowerLink™ design eliminates all past accessibility issues associated with explosionproof junction box receptacles mounted to interior pit walls. With this design an attachment receptacle, which is part of a flexible assembly, is nested in a basket mounted to the bottom of the service pit cover.

As the pit cover is opened the Class I, Division 1 and Class I, Zone 1 receptacle is presented to the user. Gone is the need to kneel on the concrete deck to mate the plug to the power supply receptacle.

We design and manufacture unique hangar solutions, including the following.

Explosionproof stainless steel connector with RFI shield

The explosionproof stainless steel connector with RFI shield has been selected as a critical component of the F-35 JSF program’s ground support operations.

Bulkhead GDT receptacles

The explosionproof bulkhead GDT receptacle comes complete with E and F relay pins, and is relied upon by commercial airlines such as American, United, Continental, Singapore and China Airlines.

Cable mounted receptacles

Vantage designed receptacle assemblies were selected for their accessibility in a US Marine Corps helicopter environment where speed, safety and performance mattered – at MCAS Cherry Point, North Carolina.

Interlocked receptacles

Our 300A interlocked receptacle with circuit breaker and contactor was developed for the US Army Corps of Engineers and Elmendorf AFB, Alaska.

Aircraft cable assemblies

We design and fabricate 400Hz assemblies combining Vantage explosionproof connectors and MS rubber-moulded connectors. Utilizing the E and F relay pins to create an electrical interlock, these flexible assemblies supply power directly to aircraft, mobile carts and frequency converters.

Aircraft hangar drop cables

Delta Airlines at Hartsfield International Airport relies on Vantage cable-mounted attachment receptacles used with motorized reels mounted in the hangar ceiling. Controlled by conveniently located pushbutton stations, these receptacles are lowered to the hangar floor, thereby eliminating excess cable in the workplace.

Integrated system design

Our hazardous area experts help ensure your installation is electrically safe and code-conforming. We understand and incorporate the hangar work environment into our system designs.

Also available is HazLoc training, Vantage connector product meetings, and installation / maintenance workshops at your facility.