Ammerall Beltech is a company producing a wide range of process and conveyor belting. It is known for developing innovative solutions for belting applications. Working closely with original equipment manufacturers and end users, Ammeraal Beltech has developed ZipLock: a special design link belt insert to make easy and fast belt exchanges possible. The solution is a perfect fit for the airport industry.

What is ZipLock?

ZipLock is an innovative belt insert invented by Ammeraal Beltech. It is placed at the belt ends to make belts connect in an easy and smooth way. The result is an almost invisible connection. The belt cover is continuous over the splice area.

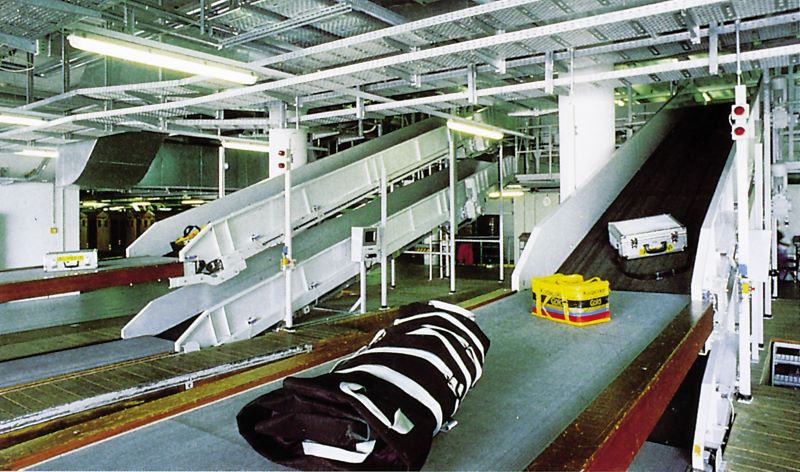

This makes it a perfect match for airports, where conveyor belts are used for safe baggage handling. Moving thousands of bags throughout an airport requires a system that is effortless and reliable. ZipLock supports these processes and brings a new quality to replacing conveyor belts at a fast pace, and with high precision.

ZipLock: major benefits

Faster belt exchange

One of the most beneficial features of ZipLock is the reduction of system downtime. Using ZipLock, you may forget about problems with belt installation. The replacement of the belt is easy and can be done within minutes. This way, you reduce maintenance time and cost, gaining increased operation time. No heavy equipment is needed and installation can be carried out safely on site. You won’t need any outside fitters or splice presses anymore. According to Ammeraal Beltech, the cost savings from using ZipLock technology may reach even 30%.

Make inaccessible accessible

The design of ZipLock enables its application in hard-to-reach places, such as conveyors at ceiling height, very short conveyors, or built-in conveyors.

Quiet belt run and higher passenger satisfaction

With ZipLock, airports can improve the passengers’ travel comfort. The ZipLock connection is almost invisible, in contrast to traditionally used mechanical belt fasteners. Its surface is smooth and causes less bottom side friction. The outcome? Quiet belt run and higher consumer satisfaction.

Safe baggage

The solution has another advantage over traditional mechanical belt fasteners- higher security of the belt load. The passengers’ baggage should be protected by all means. Less innovative methods, using metal or plastic anchors, are not only loud, but may also lead to irregular belt run, damage to the belt load, and often to the conveyor itself.

Conveyor belt breakdown can have a disastrous effect on customer confidence and the reputation of airports and airlines alike. Plus, repair times can be lengthy and costly. ZipLock connection eliminates these problems, providing silent splice and operational safety.

For more information, please follow the links on our profile.